Assignments

- The client’s objective was to improve the plant’s capacity by 20%.

- The task was to implement a new evaporator.

- An important aspect of the assignment was that the client’s production could not be halted during the installation of the new evaporator unit.

- The timing of this project was crucial, as the client had an increasing demand for its product. The new evaporator had to be commissioned within three months.

Solutions

- Saen Engineering was selected to provide engineering, project management and operator training for this project.

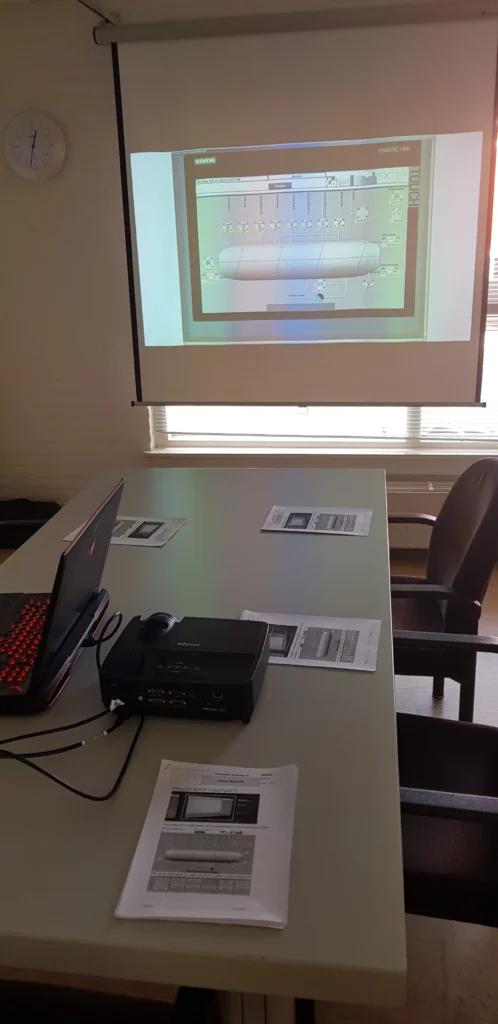

- The project included the mechanical engineering of a new evaporator, heat exchanger and piping.

- Mechanical stress analyses were performed to ensure the strength of the components and building.

- Electrical and software engineering were performed in cooperation with third parties to ensure meeting the deadline. Saen Engineering modified the software during commissioning for ultimate performance of the evaporator.

Results

- Saen Engineering involved multiple stakeholders to ensure the three-month deadline was met.

- Output increased by 20%.

- The stress analysis revealed that the floor load was too high. Therefore, Saen Engineering assigned a third party to reinforce the construction of the building.

- Documentation, reports and training of the operators were provided.