Assignments

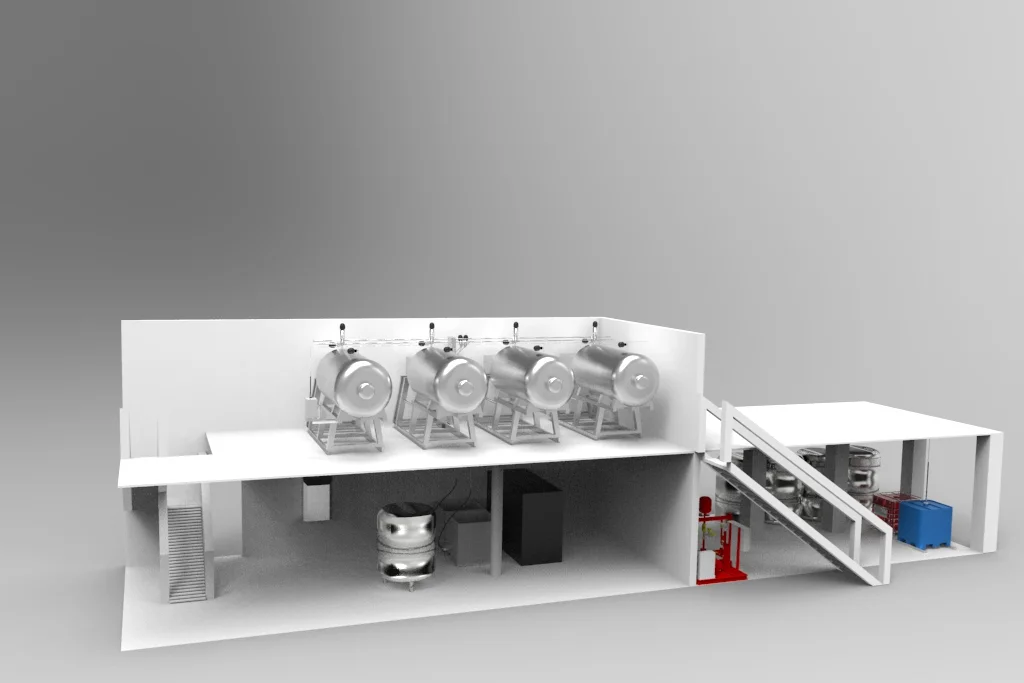

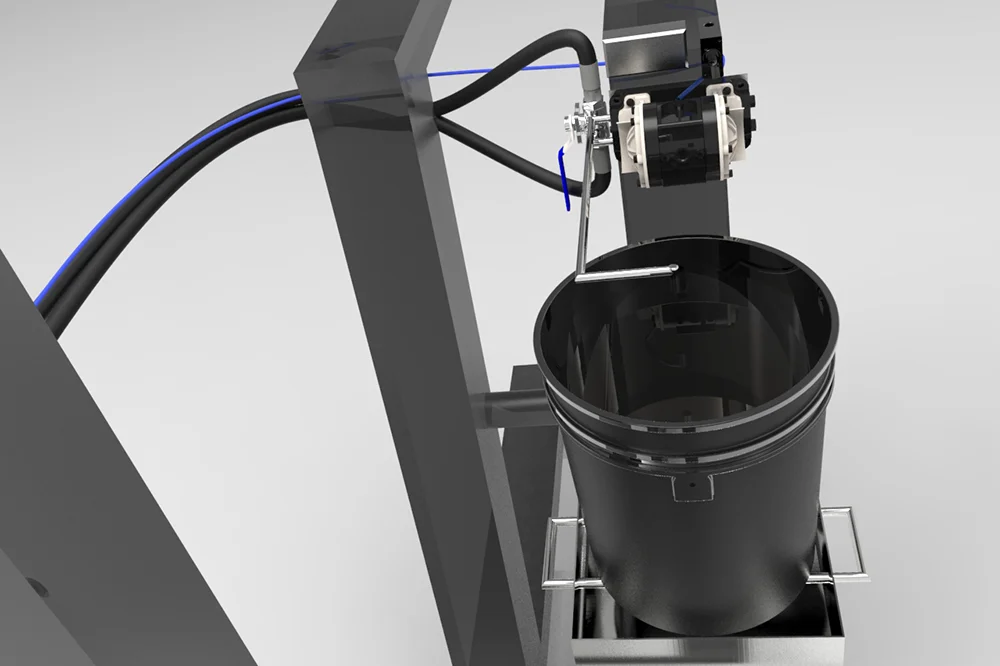

- The client’s objective was to automate the dosing process of liquids in the evaporator units

- Reduce the time operators spent manually weighing the liquids and pouring the liquids into the evaporators, using jerry cans and buckets.

- Reduction of product spillage.

Solutions

- Saen Engineering was selected to provide the electrical and mechanical engineering for this project.

- The required components, such as load cells, valves and pumps, were selected by Saen Engineering.

- Saen Engineering designed a system with three pumps, three scales and fifteen valves. The system will dose the desired amount of oil or sodium hydroxide to the evaporator.

- We provided the electrical and mechanical installation of all components.

Results

- Dosing of the liquids at the push of a button.

- Reduction of operator actions.

- 5% increase in output per evaporator.

- No more spilling of product.

- Increase in plant safety as NaOH is now dosed in a closed system.