Assignments

Solutions

Results

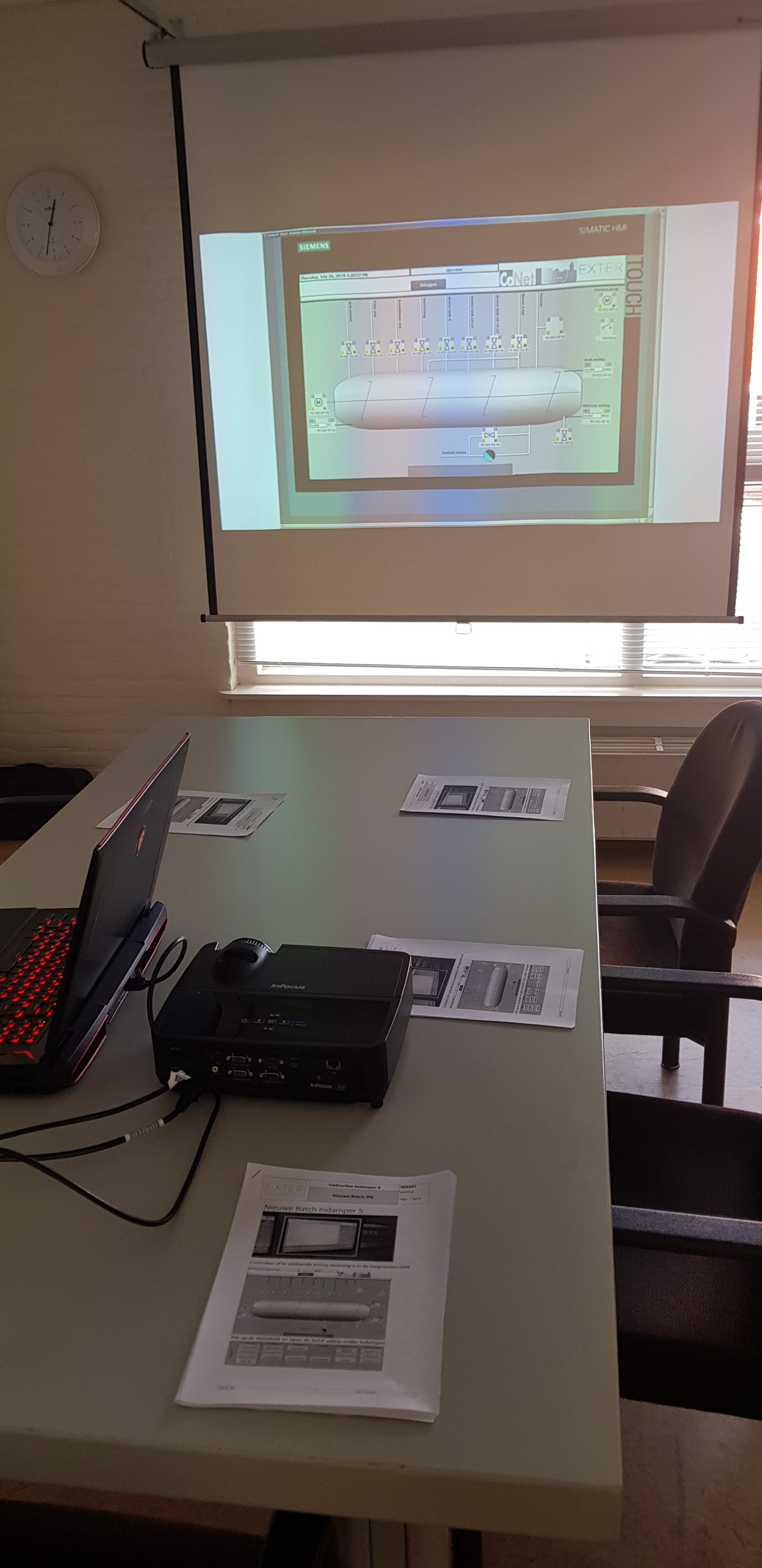

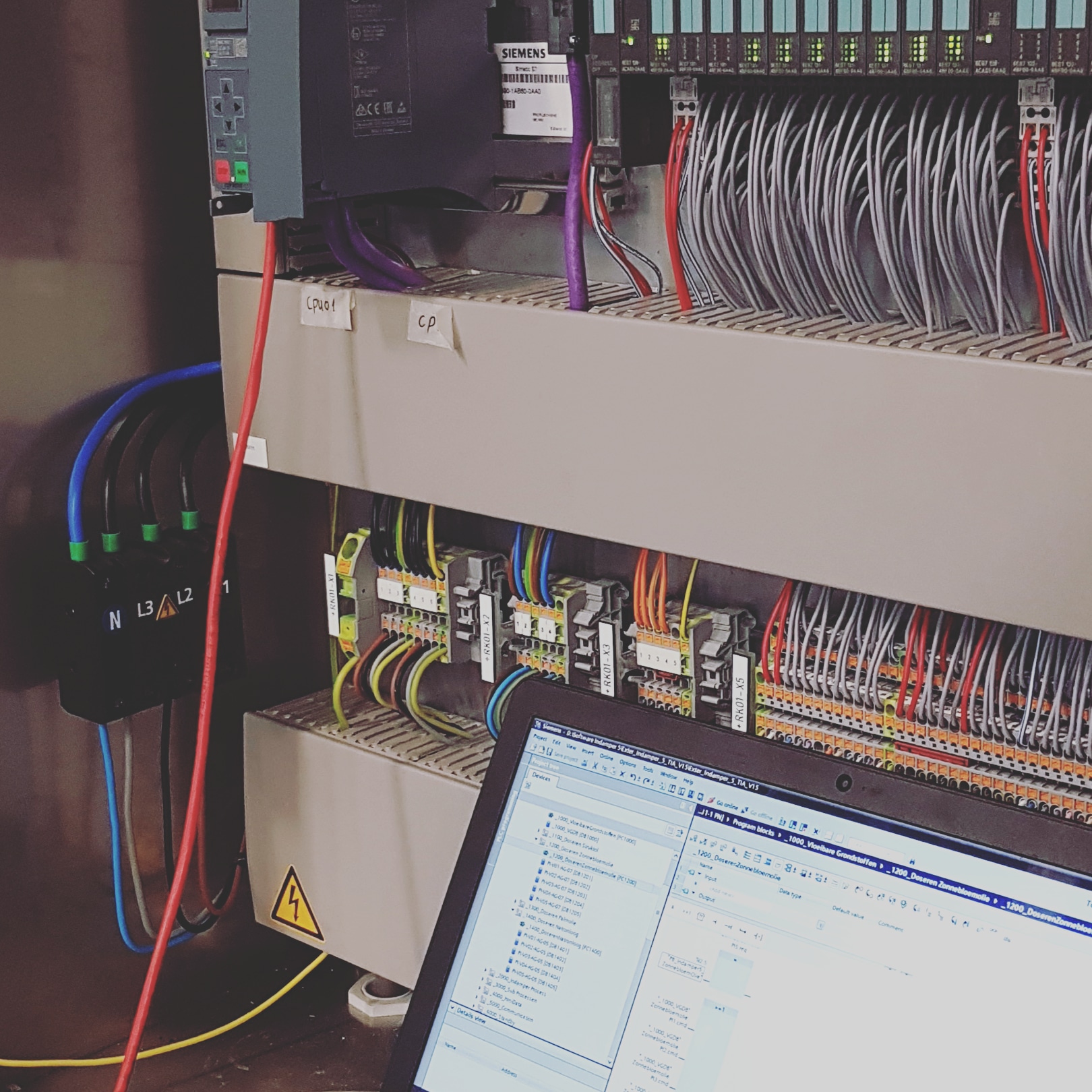

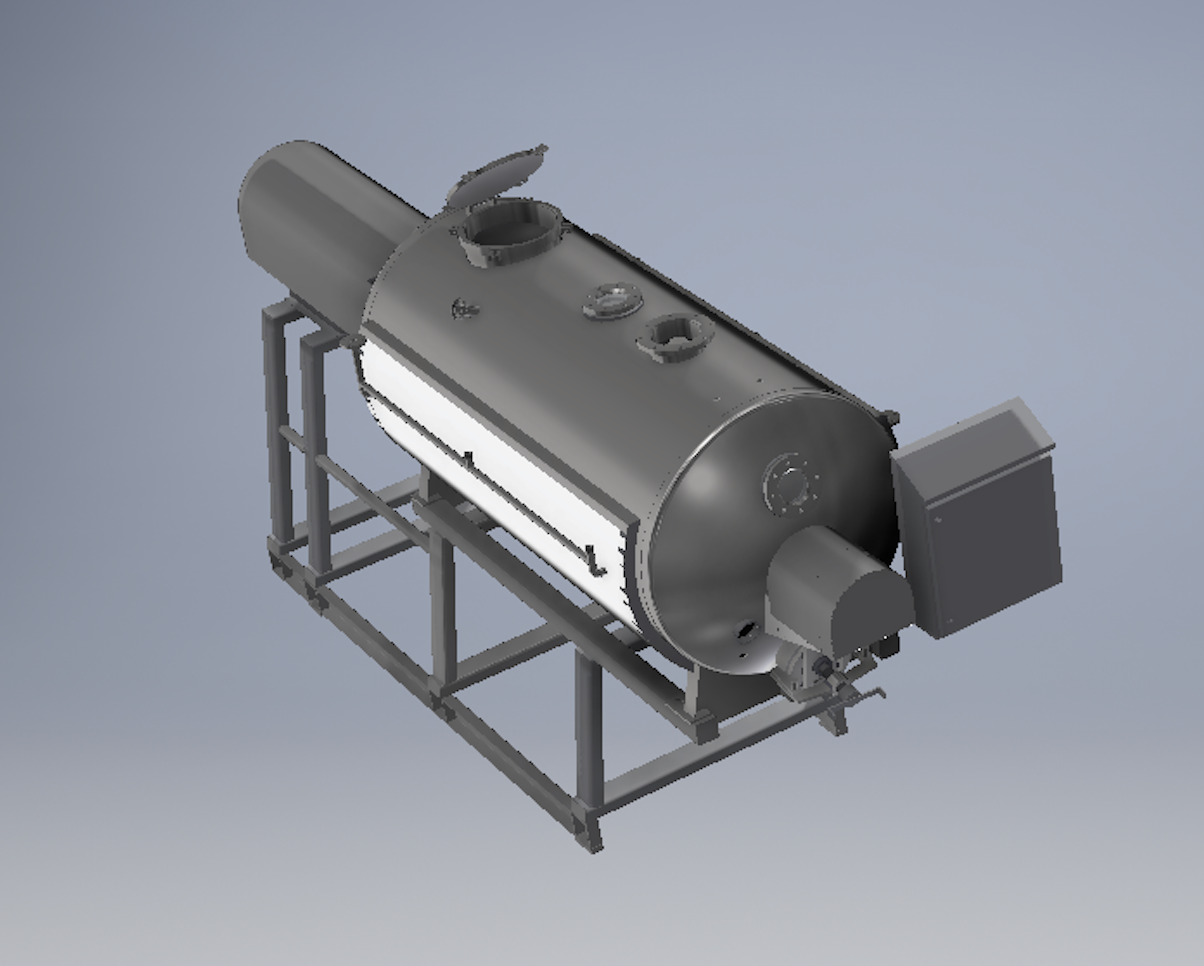

About the project

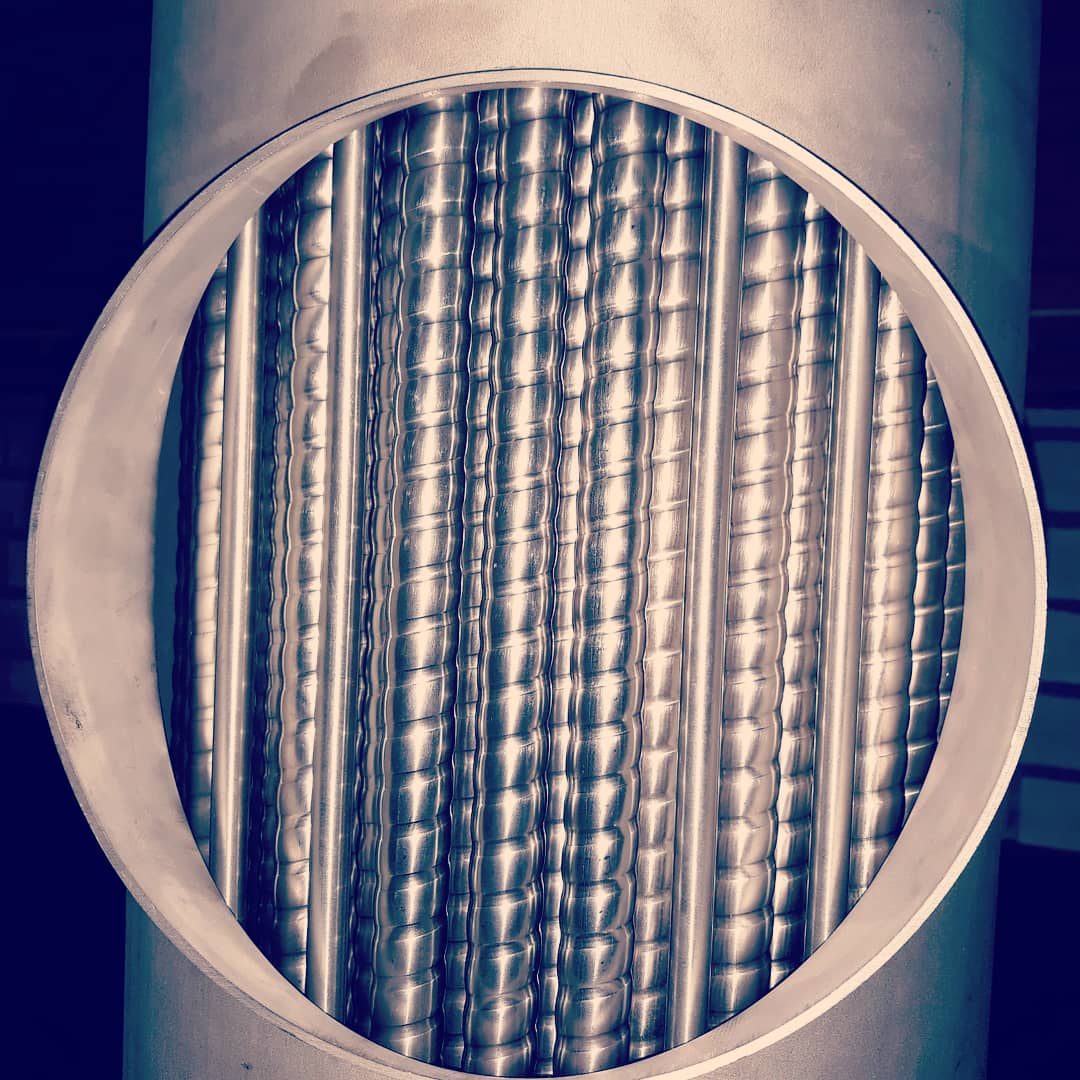

This evaporator unit is used to extract water from hydrolyzed vegetable protein (HVP).

It heats the HVP to 70°C, using steam on the bottom and sides of the evaporator.

The pressure of the evaporator is 150mbar, 70 percent of the water evaporates in 3 hours.