Assignments

Solutions

Results

About the project

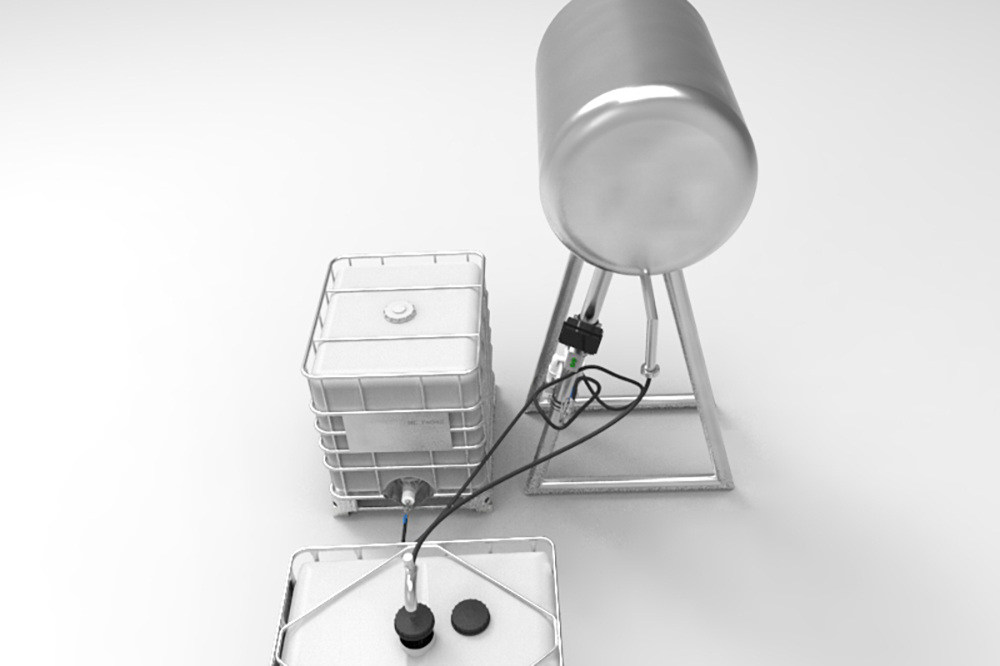

The operator had to manually pour the desired amount of caramel into the IBC using buckets.

To automate this process, a pump with a scale was installed. All the operator now had to do was enter the desired amount of

caramel in liters and the system pumps the correct amount into the IBC.